Power quality is a term that we are all seeing more of these days. What does it mean though? How can the importance of power quality be conveyed so that the average person understands the impact of power quality on their daily lives?

Most of us were introduced to electricity as kids in school when we connected D cell batteries to a tiny light in series and in parallel. Some of us were captivated and went on to learn more, others just moved on to the next lesson. For those that were not interested in investigating the wonder and complexity of electricity, the concept of power quality is confusing and gets more so once engineers begin discussing voltage transients, power factor, and harmonics. Poor power quality means higher capital expenditures, higher utility bills, lower productivity, and ultimately lower profits and decision makers in companies that depend on high quality power are typically CFO’s and their ilk, or otherwise known as the kids who were not captivated by the tiny lightbulb. This disconnect proves to be an astonishing barrier to improving power quality and collectively costs companies billions of dollars a year in losses.

Understanding power quality requires a cursory understanding of electricity. Electricity is simply charged particles (protons and electrons) resulting in energy. What do we know about energy? Energy can be neither created nor destroyed but can be transformed. Also, the laws of conservation of energy state that the energy in a system remains constant although can be changed from one form to another or transferred from one object to another. In other words, electricity on our grid or in our facility’s electrical network contains all of the electricity originally generated minus the energy that was transferred or converted prior to being used.

The conversion of electricity to heat is what most significantly impacts our electrical infrastructure from generation through transmission and even distribution to all of the grid edge recipients. Heat is electricity that has been converted to thermal energy and released into the environment, otherwise known as wasted electricity. For comprehension, think about a data center, where nearly 50% of the power bill is dedicated to cooling and exhaust. Mind you, this cooling is not converting the thermal energy back to electricity, it is simply evacuating the wasted electricity from the source as quickly and efficiently as possible. Once electricity is converted to heat it is lost. The lower the power quality, the more electricity is lost to thermal energy which makes our challenge to contain the electricity in the system without converting it to thermal energy.

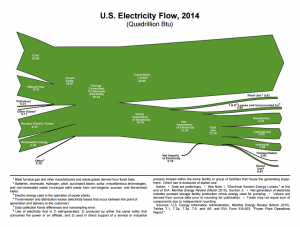

There has been enormous success in this area. It turns out that there is so much electricity converted to thermal energy that it really does not take much to reduce it. According to the EIA Electricity Flow Chart from 2014, 63% of the electricity generated was lost to conversion. Think about that. In 2014, the US generated the equivalent of 39.44 Quads of energy in electricity and 63% of that energy was lost to this thermal conversion.

There has been enormous success in this area. It turns out that there is so much electricity converted to thermal energy that it really does not take much to reduce it. According to the EIA Electricity Flow Chart from 2014, 63% of the electricity generated was lost to conversion. Think about that. In 2014, the US generated the equivalent of 39.44 Quads of energy in electricity and 63% of that energy was lost to this thermal conversion.

For some perspective, let’s dwell for just one second on exactly how much waste that amounts to. A Quad of energy is roughly equivalent to 45 million tons of coal, or for the kinesthetic learner, a pile of coal 10 feet tall, 1 mile wide, and 3.3 miles long. If we derived all of our electricity from coal, the waste alone would amount burning over 1.1 billion tons of coal annually with no electricity generated.

It stands to reason that in a system with such astronomic waste, it does not take a forensic electrical engineer to find ways to save a few dollars on a power bill. As a result, there is a billion dollar industry of power quality solutions known as compensation solutions that show mediocre success in reducing capital expenditures and utility costs, but do not correct the root of the problems. Again, I point to the enormity of the losses compared to the existing solutions. Anybody can catch a fish in a pint glass.

One of the biggest questions that I receive from non-engineers about power quality is, “Will there be any noticeable differences in my facility when I use high quality power?” The answer is a resounding yes. Let’s skip the bit about reduced capital expenditures and just focus on quality of life for the workers in a facility operating with perfect power quality. Offices will be demonstrably quieter with steady light because fluorescent ballasts stop humming and flickering. Motors, fans, and compressors begin operating at face plate efficiency with a significant reduction in noise coinciding with the reduction in vibration. Heat in motors, compressors, pumps, wires, and all electronic components will be dramatically reduced, improving the the safety and quality of life for the operating and facility engineers. You can see, hear, and feel the difference simply by using high quality electricity.

Electricity is dynamic and the quality of the electricity is limited by technology’s ability to sample analyze and correct it as it enters our facilities. The speed of electricity is not measured by how quickly electrons travel through the lines, but rather the speed of the electromagnetic wave. In a vacuum, this speed equals the speed of light, however traveling in power lines and electrical wires this speed decreases depending on the dielectric content of the wires. While the speed of electricity traveling through wires is not traveling at the speed of light it is still extraordinarily fast.

The speed at which the poor quality power enters a facility is a relevant metric for devices claiming to improve power quality. Metering devices, harmonic filters, active and passive PFC equipment, sensors and all of the existing power quality devices in the market today sample electricity in microseconds at most. A millionth of a second sounds fast, but as Rear Admiral Grace Hopper explains:

There is an enormous difference between a microsecond and a nanosecond. The fact of the matter is that in today’s world of sensitive and precision power electronics, the largest barrier to efficient power quality improvement remains the speed at which incoming electricity can be sampled, analyzed, and corrected. This physical barrier has been the single largest obstacle to perfecting incoming power quality. Accomplishing nanosecond level sampling and correction will nearly perfect a facility’s power quality and solve a century’s worth of headaches.